From concept to completion, with engineering support every step of the way

Our process is built on over 70 years of experience in delivering engineered metal components that meet the highest standards of quality and precision. Whether you need pressings, wire forms or welded assemblies, we are here to support your project from the ground up.

Design

Engineering solutions that bring ideas to life

Design is at the heart of what we do, and we have been providing our services for decades now. Our experienced team works closely with customers to develop practical, cost-effective solutions tailored to the specific requirements of each project. With a fully equipped onsite toolroom and skilled toolmakers, we offer a complete design-and-build service, creating bespoke tooling and jigs to underpin every production run.

From initial consultation through to final CAD drawings and prototypes, we ensure that every design decision is informed by a deep understanding of materials, performance, and manufacturing feasibility. This ensures that your component works just as well in reality as it does on paper.

Manufacturing

Precision and reliability built into every part

Our manufacturing capabilities cover metal pressings, wire forms and welded assemblies, produced in a wide range of materials and volumes. With hydraulic wire forming machines (up to 19mm), presses up to 80 tonnes and specialist welding stations, we are equipped to handle both simple components and complex assemblies with efficiency and consistency.

We also work with a network of approved external providers to offer secondary processes such as zinc plating, powder coating, electro painting, heat treatment and GEOMET. All partners operate under the control of our Quality Management System, giving you full confidence in every stage of production.

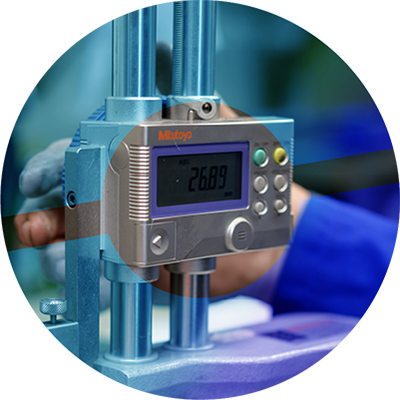

Quality Control

Focused on consistency, compliance and continuous improvement

Every component we produce is backed by rigorous quality control, from raw material inspection to final product checks. Our systems ensure full traceability and compliance with industry standards, and our commitment to continuous improvement means we’re always looking for ways to do things better.

Whether it’s maintaining tight tolerances, documenting batch records or reacting quickly to changes in specification, we take quality seriously because we know our customers do too.

Support

A partnership approach from start to finish

Support is not just an add-on, it’s embedded into every stage of our process. From your first enquiry through to delivery, you will benefit from responsive service, clear communication and a team that genuinely cares about helping your project succeed.

Our Midlands location offers easy access to major motorway links, and with our own transport and trusted delivery partners, we ensure on-time delivery you can rely on. Thanks to our adaptable workforce and customer-focused mindset, we are able to respond quickly to changes, resolve challenges and keep your supply chain running smoothly.

Contact us

Talk to our team

Simply send us your queries and questions and a member of our team will be in touch.

Visit us

If you would like to talk to us in person, you can find us at our manufacturing facility in Sutton Coldfield.